|  | Topic : Electronic Supercharger - Chapter 4 |  |

| | | DizzE | | Thor |  |  | | Reg. Date | : | 12/07/2010 | | Posts | : | 3,141 | | Location | : | Sunnyvale, CA, United States |

|

| | Posted : 11 Feb 2014 - 19:51 Post title : Electronic Supercharger - Chapter 4 | | |

We have a message! Alain did reply. He has been through the mill backwards, like I thought, but seems to be a bit more optimistic now.

So, while I doubt he will be getting around to this project anytime soon, I am happy to report he is still rowing hard, got past some big rocks, indeed, and is beginning to get back to his business concerns.

To honor that, we begin #4.

I have the parts on the way for a new round of tests. A power box and a manual control, and my DC power supply can get a spin on the motor in the frame with the coupling part. And I will most likely have to redesign the entire thing, for dynamic loading runs.

No sense filling the blower with special traction fluid, if I cannot transfer torque.

Hey Alain!

| | Post edited by DizzE on 11 Feb 2014 - 20:50 |

|

| | | Linkdog | | Thor |  |  | | Reg. Date | : | 10/02/2011 | | Posts | : | 2,917 | | Location | : | Groveland, FL., United States |

|

| | Posted : 11 Feb 2014 - 20:05 Post title : Re: Electronic Supercharger - Chapter 4 (Re: DizzE) | | |  To Alain. To Alain.

| Never drink from a cow with one udder! 2010 1600 Blue&White ( of course ) Long TORS and HP filter. 2010 1600 Blue&White ( of course ) Long TORS and HP filter.

|

|

| | | mat1600 | | Thunderbird |  |  | | Reg. Date | : | 06/03/2010 | | Posts | : | 8,596 | | Location | : | Bridlington, Democratic Independant State of Yorkshire, United Kingdom |

|

| | Posted : 11 Feb 2014 - 21:47 Post title : Re: Electronic Supercharger - Chapter 4 (Re: Linkdog) | | |

Linkdog wrote:

To Alain. To Alain. |

|

...and Diz.... for sticking with it.

| My first natural instinct is to breathe. My second is to evade tax's.

|

|

| | | Leethal | | Zeus |  |  | | Reg. Date | : | 24/01/2011 | | Posts | : | 6,403 | | Location | : | Australia |

|

| | Posted : 11 Feb 2014 - 22:10 Post title : Re: Electronic Supercharger - Chapter 4 (Re: mat1600) | | | Great news all round.

| Experience is something you get just after you needed it

1600,short tors, Meerkat bypass, Dyno tune, real headlight,plenty of chrome,switchblade pegs, Hagon Nitro shocks & Ikon progressive fork springs etc. Scorpion Western Low handlebars. PH adjustable fork caps.

|

|

| | | Linkdog | | Thor |  |  | | Reg. Date | : | 10/02/2011 | | Posts | : | 2,917 | | Location | : | Groveland, FL., United States |

|

| | Posted : 12 Feb 2014 - 00:11 Post title : Re: Electronic Supercharger - Chapter 4 (Re: mat1600) | | |

mat1600 wrote:

Linkdog wrote:

To Alain. To Alain. |

|

...and Diz.... for sticking with it.  |

|

| Never drink from a cow with one udder! 2010 1600 Blue&White ( of course ) Long TORS and HP filter. 2010 1600 Blue&White ( of course ) Long TORS and HP filter.

|

|

| | | DizzE | | Thor |  |  | | Reg. Date | : | 12/07/2010 | | Posts | : | 3,141 | | Location | : | Sunnyvale, CA, United States |

|

| | Posted : 12 Feb 2014 - 01:09 Post title : Re: Electronic Supercharger - Chapter 4 (Re: Linkdog) | | | Pretty small, heavy heat sink, two fans.

|

|

| | | DizzE | | Thor |  |  | | Reg. Date | : | 12/07/2010 | | Posts | : | 3,141 | | Location | : | Sunnyvale, CA, United States |

|

| | Posted : 12 Apr 2014 - 22:14 Post title : Re: Electronic Supercharger - Chapter 4 (Re: Linkdog) | | | One small step.

I got around to setting up the basic test. Too many projects.

It works. 12v will power the motor via the dial. The other battery is to power the fans on the Electronic Speed Controller.

No problem for real life. It just takes a little step down, voltage regulator to drop 12v down to 7v.

I have to understand how to replace that dial with a look-up table that crosses the throttle position with the crank speed and outputs boost value for the blower. The little dial box already outputs the values, so maybe I can build a little chip onto it and have that be the "dial" for the main ECU to bring in boost at say TP 60%+ and RPM 3000+.

Should be easy, right?

| | Post edited by DizzE on 12 Apr 2014 - 22:16 |

|

| | | DizzE | | Thor |  |  | | Reg. Date | : | 12/07/2010 | | Posts | : | 3,141 | | Location | : | Sunnyvale, CA, United States |

|

| | Posted : 12 Apr 2014 - 23:44 Post title : Re: Electronic Supercharger - Chapter 4 (Re: DizzE) | | | The control output, the "dial", is a pulse width modulated waveform. I'm just taking notes here on the guts of matter at hand.

Basically, the dial is analog, but needs to be converted to a digital array. It needs to be designed into a 2D digital array, the "table."

That's not so hard. The throttle position is in percent of a voltage. And the crank speed sensor with be a blip to to count for each rev.

Why didn't I pay more attention in Integrated Circuits class?

Anyway, I have this already. I just need an T-bird input scheme, not a hand dial.

Servo tester:

The 555 IC is wired as an oscillator. the pot determines the pulse width of the output (pin 3) any where from 1.5 ms to about 2.5mseconds (?) ; this pulse widh determines which way the servo motor will turn (left or right) and how much it will turn. the potentiometer works w the timing capacitor and the 555 functions as an astable multivibrator.

| | Post edited by DizzE on 13 Apr 2014 - 01:10 |

|

| | | MotorMac | | Jupiter |  |  | | Reg. Date | : | 29/08/2010 | | Posts | : | 1,787 | | Location | : | Nor Cal, United States |

|

| | Posted : 13 Apr 2014 - 00:35 Post title : Re: Electronic Supercharger - Chapter 4 (Re: DizzE) | | |

DizzE wrote:

I'm just taking notes here on the guts of matter at hand.

|

|

Good thing, too. Heaven help us if YOU have a question! ;-)

|

|

|

| | | Leethal | | Zeus |  |  | | Reg. Date | : | 24/01/2011 | | Posts | : | 6,403 | | Location | : | Australia |

|

| | Posted : 13 Apr 2014 - 00:38 Post title : Re: Electronic Supercharger - Chapter 4 (Re: MotorMac) | | | I think things have moved on slightly since I was an electrician in the 70's Navy.

| Experience is something you get just after you needed it

1600,short tors, Meerkat bypass, Dyno tune, real headlight,plenty of chrome,switchblade pegs, Hagon Nitro shocks & Ikon progressive fork springs etc. Scorpion Western Low handlebars. PH adjustable fork caps.

|

|

| | | Dags | | Set |  |  | | Reg. Date | : | 01/11/2013 | | Posts | : | 468 | | Location | : | N.S.W, Australia |

|

| | Posted : 13 Apr 2014 - 09:52 Post title : Re: Electronic Supercharger - Chapter 4 (Re: DizzE) | | | You had me at "pulse width modulated waveform", but seriously, looking forward to following this thread, thanks DizzE

|  Dags Dags

| | Post edited by Dags on 13 Apr 2014 - 09:53 |

|

| | | DizzE | | Thor |  |  | | Reg. Date | : | 12/07/2010 | | Posts | : | 3,141 | | Location | : | Sunnyvale, CA, United States |

|

| | Posted : 13 Apr 2014 - 15:44 Post title : Re: Electronic Supercharger - Chapter 4 (Re: Dags) | | | Well, they had me there, also.

But, let's see if we can make that a more simple concept.

In the old days, we had model planes (and this is the same gear brought forward 50 years.)

We used something call PPM. Pulse Proportion Modification. There were always plus and minus pulses.

We are talking very fast pulsing per second, you need an O-scope to see.

But, what was the proportion, of pos to neg? 50/50? OK> That the neutral position of the servo.

It is a power mad scheme, as you can tell. And it is slow, since the math has to be done before the signal goes to the servo.

If you modify the width of the pulse in microseconds, a servo can be told by the receiver, we just got a 300 microsecond pulse on your channel. Go to Neutral, now, new pulse length = 2% down, now 3%, now neutral, now 2% up, all on the length of the pulses received, not the proportional math.

Clear as mud.

IAC, I think I know what to do for this now. I use my little embedded hobby board, Arduino Uno, to program another chip.

"Use the Servo library distributed with Arduino. Connect the servo power and ground to a suitable power supply (a single hobby servo can usually be powered from the Arduino 5V line). Recent versions of the library enable you to connect the servo signal leads to any Arduino digital pin."

Just this little bit of code here, is enough to cause the blower to sweep up and down, min to max blow. So the idea is to add the 2D array lookup and some attach/detach code for the bike to wake it up and control it with throttle position.

Link -------------

#include |Servo.h>

Servo myservo; // create servo object to control a servo

int angle = 0; // variable to store the servo position

void setup()

{

myservo.attach(9); // attaches the servo on pin 10 to the servo object

}

void loop()

{

for(angle = 0; angle | 180; angle += 1) // goes from 0 degrees to 180 degrees

{ // in steps of 1 degree

myservo.write(angle); // tell servo to go to position in variable 'angle'

delay(20); // waits 20ms between servo commands

}

for(angle = 180; angle >= 1; angle -= 1) // goes from 180 degrees to 0 degrees

{

myservo.write(pos); // tell servo to go to position in variable 'pos'

delay(20); // waits 20ms between servo commands

}

}

--------------------------------------------

Then I can use this technique for programing a chip that T-bird can talk to, via the crank speed sensor and the throttle position sensor.

Link

"We use an Arduino to program other ATmega without bootloader . This technique allows you to use all flash memory for code and make boards using new ATmega, cheaper than those with bootloader...."

"...If we use Arduino for a specific use, we can integrate it into a specific circuit and program the micro in a way that it performs as single firmware. We may so remove the bootloader and leave to the firmware the entire program memory.

| | Post edited by DizzE on 13 Apr 2014 - 17:01 |

|

| | | Bender | | Chaac |  |  | | Reg. Date | : | 26/09/2010 | | Posts | : | 659 | | Location | : | Toowoomba, Queensland, Australia |

|

| | Posted : 22 Apr 2014 - 12:05 Post title : Re: Electronic Supercharger - Chapter 4 (Re: DizzE) | | | Thats all Great stuff DizzE, I have 1 question how long have they been making Helmets that size ??

| BENDER Four wheels move the body. Two wheels move the soul. Four wheels move the body. Two wheels move the soul.

Thunderbird 1600, Foran exhaust,cat eliminator,Twin T Bars, K and N filter, Led Headlight, Rivco driving Lights, Viking Bags,quick release sissy Bar,.Joker oil pressure Gauge met-cruise seat Dyno Tune + more

|

|

| | | DizzE | | Thor |  |  | | Reg. Date | : | 12/07/2010 | | Posts | : | 3,141 | | Location | : | Sunnyvale, CA, United States |

|

| | Posted : 02 May 2014 - 13:49 Post title : Re: Electronic Supercharger - Chapter 4 (Re: Bender) | | | I know what you mean brother, I am working with some major brain buckets at work. Sad to say, this is quite small potato to them. Baby School, more like,

There is only one guy at work, a real buddy of mine with a turbocharged airplane and auto, that I can talk to. He can somewhat accept the fact that I am allowed in the building but still struggle with coding arrays and function.  Some of these other guys would want my badge and resignation. Not kidding, there are few real techno-ego-hardasses with the emotional ingenuity of Lord or the Flies Island folk. Some of these other guys would want my badge and resignation. Not kidding, there are few real techno-ego-hardasses with the emotional ingenuity of Lord or the Flies Island folk.

My friend just said, after smiling at me (and patting my head) "Maybe just put the array in a function?"  But he knows me. AH HAAAAAAA!!!! But he knows me. AH HAAAAAAA!!!!

So, here are the guts. I have a WOT example that complies. Blower on/off is jsut wide open throttle. But we need gain control to make it smooth and much safer. This funtion will complie and all I have to do is pass it the RPM and Throttle Postion. It returns the Gain multiplier from the loop up table, ie the array.

So, without a fancy user interface, I can just include this function instead of WOT code that right now it only linear, only tied to RPM. With this function I can edit for more or less gain in 100 cells, to create BEST POWER when we are on the Dyno.

------------------

float gainArrayLookup (int y, int x) {

float array[10][10]=

{

//55%//50%//65%//70%//75%//80%//85%//90%//95%//100%//Throttle Position/Crank Speed

{1.00,1.00,1.00,1.00,1.00,1.00,1.00,1.00,1.00,1.00,}, // 6500 RPM

{1.00,1.00,1.00,1.00,1.00,1.00,1.00,1.00,1.00,1.00,}, // 6000 RPM

{1.00,1.00,1.00,1.00,1.00,1.00,1.00,1.00,1.00,1.00,}, // 5500 RPM

{1.00,1.00,1.00,1.00,1.00,1.00,1.00,1.00,1.00,1.00,}, // 5000 RPM

{1.00,1.00,1.00,1.00,1.00,1.00,1.00,1.00,1.00,1.00,}, // 4500 RPM

{1.00,1.00,1.00,1.00,1.00,1.00,1.00,1.00,1.00,1.00,}, // 4000 RPM

{1.00,1.00,1.00,1.00,1.00,1.00,1.00,1.00,1.00,1.00,}, // 3500 RPM

{1.00,1.00,1.00,1.00,1.00,1.00,1.00,1.00,1.00,1.00,}, // 3000 RPM

{1.00,1.00,1.00,1.00,1.00,1.00,1.00,1.00,1.00,1.00,}, // 2500 RPM

{1.00,1.00,1.00,1.00,1.00,1.00,1.00,1.00,1.00,1.00} // 2000 RPM

};

return array[y][x];

};

----------------------

I have all the parts now to solder up a little control board based on the AT85Tiny chip. The entire thing will fit in an Altoid Smalls, tin,

I only have 5000 bytes of memory, but it looks like I can do this with only 4000. Maybe just 100 lines of code. (our product at work, is well over 1.5 million lines.)

Getting there.

| | Post edited by DizzE on 02 May 2014 - 13:55 |

|

| | | DizzE | | Thor |  |  | | Reg. Date | : | 12/07/2010 | | Posts | : | 3,141 | | Location | : | Sunnyvale, CA, United States |

|

| | Posted : 04 May 2014 - 21:03 Post title : Re: Electronic Supercharger - Chapter 4 (Re: DizzE) | | | OK, I have something that will compile at least, for the ATtiny85 processor.

I wrote 3 functions to do the jobs, One complexity is the signal from the crank sensor has to be sampled for a time and counted, then reset. Another hurdle was setting up the clock dividers to get a timing function. That function, I call SIGNAL().

It really has two counters against one clock. The first counter I need to do a refresh on the blower speed every 20 ms. It is just a limitation of this processor. And, the other count is a 200 ms counter that simply sets a flag when it's done and resets to count again.

If what I think is correct, the bike's crank speed sensor will pulse once every revolution. (have to check that) That means at 6000 RPM, I still have to wait 10 ms, for even one pulse, and at 100 milliseconds, I only see 10 pulses. Not fine grain enough, so I wait 200 ms and see 20 pulses for 6000 RPM.

What this the means for a 16mHz processor is it has a lot of time on its hands, down in the nanosecond world, and a lot to do (even if that is just goof off.)

It can't sit and wait though the 10 milliseconds of nano-centuries, to finally get one pulse. So, that means it has to be event driven. The processor can't pause, we have to interrupt his boredom tasks, which we call the housekeeping loops.

I attach a processor Interrupt to the pin with the crank speed signal, and when a rising edge of voltage is detected, ( A PULSE!!!, FINALLY) the Interrupt routine calls my 2nd function pulseCount(). And that feeds the lookup table, my 3rd function.

The control loop() is simply waiting for 50% throttle to check RPM vs TP and look up a gain multiplier to apply to the blower speed.

Now to build a test. Parts will be here next week. I'll start with a breadboard of course, but it will all go in this little I/O box, for the bike.

| | Post edited by DizzE on 04 May 2014 - 21:11 |

|

| | | DizzE | | Thor |  |  | | Reg. Date | : | 12/07/2010 | | Posts | : | 3,141 | | Location | : | Sunnyvale, CA, United States |

|

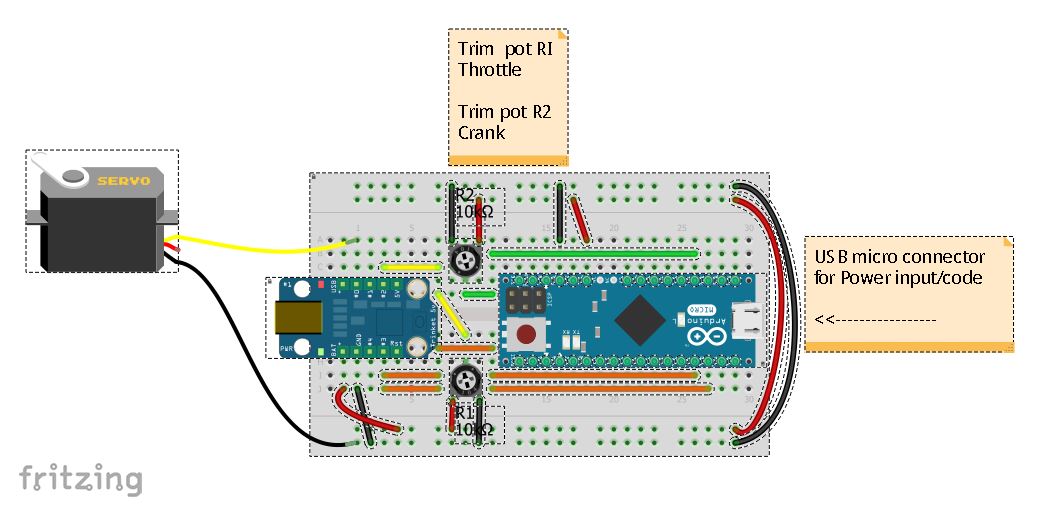

| | Posted : 12 May 2014 - 01:31 Post title : Re: Electronic Supercharger - Chapter 4 (Re: DizzE) | | | By using another processor (on the right) I can simulate a crankshaft sensor on trim pot R2 and then R1 is a an analog

voltage trimmer to simulate the throttle position sensor.

Red = +5 V

Black = Ground

Green = R2 output to Arduino Mini

Orange = Square wave representing crank speed into Adafruit Trinket (on left)

Yellow = R1 output to Adafruit Trinket

I'll start testing with only 5 volts running a small RC servo. The servo is the stand in for the 12 Volt/1000 Amp, Electronic Speed Controller

that runs the blower motor. It takes the exact same pulse codes. This is the bike interface board prototype on a breadboard planning tool.

What could possibly go wrong?

| | Post edited by DizzE on 12 May 2014 - 01:37 |

|

| | | MotorMac | | Jupiter |  |  | | Reg. Date | : | 29/08/2010 | | Posts | : | 1,787 | | Location | : | Nor Cal, United States |

|

| | Posted : 14 Jun 2014 - 16:50 Post title : Re: Electronic Supercharger - Chapter 4 (Re: DizzE) | | | How's that blower coming? Expiring minds wanna know!

|

|

|

| | | DizzE | | Thor |  |  | | Reg. Date | : | 12/07/2010 | | Posts | : | 3,141 | | Location | : | Sunnyvale, CA, United States |

|

| | Posted : 15 Jun 2014 - 13:46 Post title : Re: Electronic Supercharger - Chapter 4 (Re: MotorMac) | | | Well, if I was better coder, and a better thinker, I'd be farther along.

I am still assembling the test pieces, but I have also been doing a maintenance turn, got the wheels and tank off, etc.

Progress is I have my friend at work looking at the code, if he will do it. It is kinda like asking someone to read your poetry.

Easy to agree to and not really spend any time on it. Looks good. :) We'll see.

I found my Arduino board, so now I have oscilloscope software snooping to check the bike, with that.

When I took out the throttle bodies to replace a broken throttle cable (big job, that), I got a good look at how the

electrical runs from the 2 sensors I will use.

And my wife knows a lot more about breakpoints and tracebacks for troubleshooting, than I do. So, I need her

to look at it too, beyond....Looks good!

I did put together the test breadboard and got enough result to see I was overrunning the buffer I had setup to count

into the lookup table.

And I figured out what the problem was there. I have to put the table in protected memory, make it static, limit it to 8 bits, etc,

so it does not have to create it each run thru the loop and blow out the memory space after 4 seconds.

And then I have to go thru it in a timing sense and count the microseconds it takes to do "stuff" and factor

that in with "delay function" in various places.

I think I will run the processor at only 8 mHz instead of 16. I think that will slow it down to bike brain speed.

And if you have ever worked with these silly breadboard, it can be very frustrating at times, to see you knocked that wire out, again.

So, if you haven't caught on yet, this is the hard part.

I have to figure out a way to set up breakpoints and just work tiny pieces of code at a time and trace the path of

the logic by having it stop and output a variable value and make sure that is what I expect to see.

It is very hard for me to torture code in the summer, however. Slow going, at this point.

| | Post edited by DizzE on 15 Jun 2014 - 13:47 |

|

| | | MotorMac | | Jupiter |  |  | | Reg. Date | : | 29/08/2010 | | Posts | : | 1,787 | | Location | : | Nor Cal, United States |

|

| | Posted : 15 Jun 2014 - 17:14 Post title : Re: Electronic Supercharger - Chapter 4 (Re: DizzE) | | | Without a doubt, this has got to be the most over-the-top project on any MC forum.

Will be interesting to see how the motor holds up to being supercharged, but I'm sure you've already done the math.

Don't see breadboards being around much longer as components are so wee-tiny these days as to be impossible to handle. Was fun to experiment with tho, had mine out awhile back with a 555 blinking alarm light in dash as if armed. Wish I had time to get into the Arduino kits, those things look really cool, surprised to learn they use C/C++. Was expecting something more basic like Basic. Much more sophisticated and powerful than I thought, with a whole eco system built around 'em. Hmmm..... Much more interesting than, say, adjusting the chirp out of my drive belt. Again.

Please keep us informed as to progress, fascinating stuff!

|

|

|

| | | DizzE | | Thor |  |  | | Reg. Date | : | 12/07/2010 | | Posts | : | 3,141 | | Location | : | Sunnyvale, CA, United States |

|

| | Posted : 16 Jun 2014 - 16:08 Post title : Re: Electronic Supercharger - Chapter 4 (Re: MotorMac) | | |

Well, you get the wee-tiny components and solder on pin headers.  Then you can breadboard. Then you can breadboard.

Link

This is my project stuff source. These embedded processors run compiled language, unlike BASIC, which is interpreted slowly,

line by line. There is very limited command set, and easier to learn than basic. And it all fits in Kb of memory, not Mb or Gb.

The main advance for me, was this weekend I finally got Visual Studio running with the Arduino plugin.

This IDE (interactive Dev Environment) uses the Arduino IDE under the covers, but surfaces all this rich, de-bugging feature set that is

missing in the Arduino base IDE.

So, now I have to go back and pick my brain apart again and carefully see what is happening, at every step, by having a breaks (stops) in the program.

I will examine what change was picked up by the variable in question or NOT, and all the other gottchas.

Just because the code can compile in the IDE doesn't mean it will work as intended. And mine doesn't yet.

It will be working enough to test the blower, sometime this year, I imagine. I hope.

|

|

| | | DizzE | | Thor |  |  | | Reg. Date | : | 12/07/2010 | | Posts | : | 3,141 | | Location | : | Sunnyvale, CA, United States |

|

| | Posted : 12 Jul 2014 - 18:55 Post title : Re: Electronic Supercharger - Chapter 4 (Re: DizzE) | | | Finally!! I have a working concept.

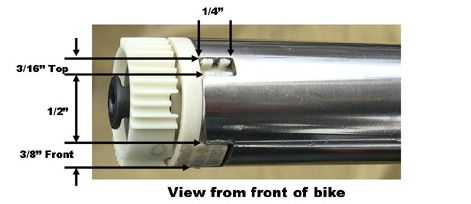

The main thing is, I can see the alternator rotor has what is called a tone ring. It is slightly mentioned in the Manual about troubleshooting damaged teeth.

So, instead of slowly counting rpms based on a countdown, resetting timer of 200 millis., I can use the fastest clock, 62.5 ns, to measure the speed between any two of the 24 teeth.

The reason it is called a tone ring is the frequency of teeth flying by under the magnetic sensor at internal combustion speeds can produce a tone we can hear if it went to a speaker. I have a speaker running at slightly above idle, right now. A440. For us the idle speed of 1000 is one tooth every 2.5 milliseconds. This makes it a lot easier for timing of the code.

The idea now.

if throttlePosition is at or above 50%

call toneRing()

if toneRing is above at or 3000 rpm

call blowerControl(toneRing, throttlePosition)

else check again

Let's just say, since all this is happening on a microsecond level based on a nanosecond clock, the processor has plenty of time and will mostly be waiting for the next tone ring tooth, even if activated. .413 milliseconds interval is 6000 RPM of the tone ring. That means, the engine speed changes and wrist changes are meaninglessly slow and the processor is always ready for the next cycle within a few microseconds.

Getting there.

|

|

| | | DizzE | | Thor |  |  | | Reg. Date | : | 12/07/2010 | | Posts | : | 3,141 | | Location | : | Sunnyvale, CA, United States |

|

| | Posted : 12 Jul 2014 - 18:57 Post title : Re: Electronic Supercharger - Chapter 4 (Re: DizzE) | | | BTW, Visual Studio was a bust.

Also, the Arduino Micro and the Trinket are just not good communicators with Windows 8. I will use the Arduino UNO, rugged version on the bike.

| | Post edited by DizzE on 12 Jul 2014 - 22:47 |

|

| | | Rachael7 | | Chaac |  |  | | Reg. Date | : | 17/05/2013 | | Posts | : | 511 | | Location | : | Greenfield, MA, United States |

|

| | Posted : 12 Jul 2014 - 20:18 Post title : Re: Electronic Supercharger - Chapter 4 (Re: DizzE) | | | Very cool! Sounds like some good progress. Thanks for the update!

| 2012 Thunderbird 1600, Short TORS, Triumph performance filter, TORs tune, Longhaul solo seat, Highway Hawk tubular solo rack, Dart flyscreen, engine bars, highway pegs, Clearwater Darla driving lights, custom flash-to-pass switch, Hagon 2810 rears, Thunderbike fork caps, Custom rear sets

|

|

| | | DizzE | | Thor |  |  | | Reg. Date | : | 12/07/2010 | | Posts | : | 3,141 | | Location | : | Sunnyvale, CA, United States |

|

| | Posted : 12 Jul 2014 - 22:44 Post title : Re: Electronic Supercharger - Chapter 4 (Re: Rachael7) | | | And I just got it working.

I use a tone generator to give me a frequency to measure. And I can see it changing the map table results as I change the "crank tone."

It gives zero blower and looks again until the conditions are met. It's very fast.

So.... Onward!

I have the test bed already set up and next I will see if if can change a little servo and then test the blower motor speed, itself.

| | Post edited by DizzE on 12 Jul 2014 - 22:46 |

|

| | | Linkdog | | Thor |  |  | | Reg. Date | : | 10/02/2011 | | Posts | : | 2,917 | | Location | : | Groveland, FL., United States |

|

| | Posted : 13 Jan 2015 - 23:13 Post title : Re: Electronic Supercharger - Chapter 4 (Re: DizzE) | | | Dizze, how is this going? It's been a while.

| Never drink from a cow with one udder! 2010 1600 Blue&White ( of course ) Long TORS and HP filter. 2010 1600 Blue&White ( of course ) Long TORS and HP filter.

|

|

| | | DizzE | | Thor |  |  | | Reg. Date | : | 12/07/2010 | | Posts | : | 3,141 | | Location | : | Sunnyvale, CA, United States |

|

| | Posted : 14 Jan 2015 - 00:01 Post title : Re: Electronic Supercharger - Chapter 4 (Re: Linkdog) | | | I have nothing to report but failure. I can't get the motor controller to arm properly. So I have not been able to test the code.

I think I am waiting for better motor controller. Maybe this year.

|

|

| | | MotorMac | | Jupiter |  |  | | Reg. Date | : | 29/08/2010 | | Posts | : | 1,787 | | Location | : | Nor Cal, United States |

|

| | Posted : 15 Jan 2015 - 16:48 Post title : Re: Electronic Supercharger - Chapter 4 (Re: DizzE) | | | That is some toy store! Surprised you have to go all the way to NYC for electronic goodies, should think you'd be surrounded by the stuff.

Forgive my ignorance here, but wouldn't throttle-by-wire simplify things a bit? Seems to be where we're headed, tho the idea of hanging a pot on the end of a motorcycle handlebar sounds like trouble to me. Would have to be one heavy-duty, well-sealed pot.....

(Pic ripped from Flanders web site showing mods to handlebar end: Link )

|

|

|

|

| |

| |

|